Material Supply Chamber

What is a material supply chamber?

A dispensing booth is a type of cleanroom device that creates a limited clean area to protect operators and their surroundings from hazardous substances during mixing and weighing,… Ingredients, usually powdered ingredients.

It is a type of cabin, equipped with specialized equipment to create a stable, one-way airflow (casing flow), the pressure inside the cabin is always maintained at negative pressure, thereby protecting the operator and preventing dangerous chemicals from being released into the external environment.

Structure of material supply chamber

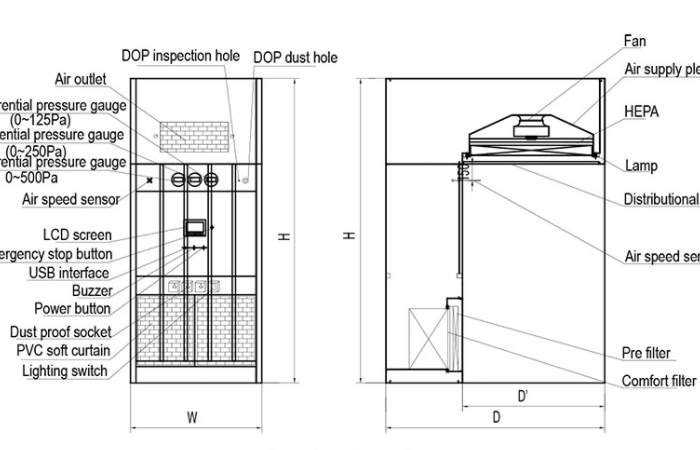

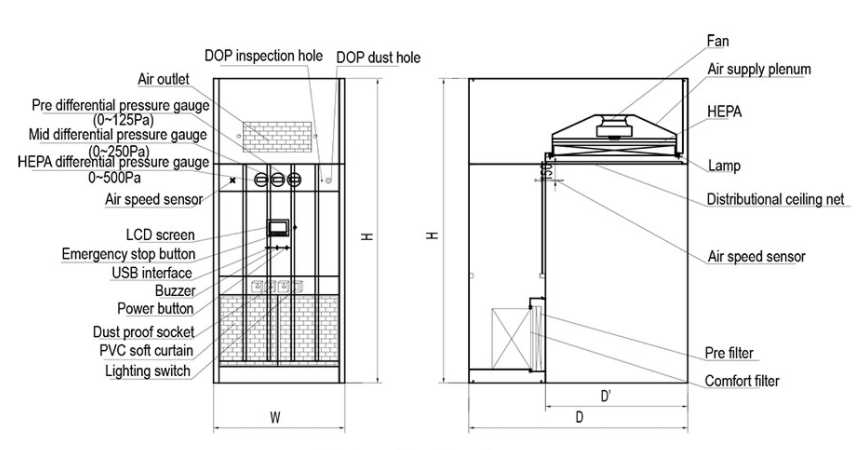

An allocation chamber consists of 2 main parts: the working compartment and the air filter unit.

Structure of material supply chamber

The entire case frame is made from 304 stainless steel or 316 stainless steel. The fan is responsible for creating and maintaining a stable casable flow in the working compartment. A standard weighing chamber will be equipped with 3 filters: Pre-filter, intermediate filter and high efficiency filter (HEPA), in addition it is equipped with an HMI touch screen for control and 3 pressure differential clocks to monitor the condition of the filters.

Operation of the grant room

Principles of operation of material supply chamber

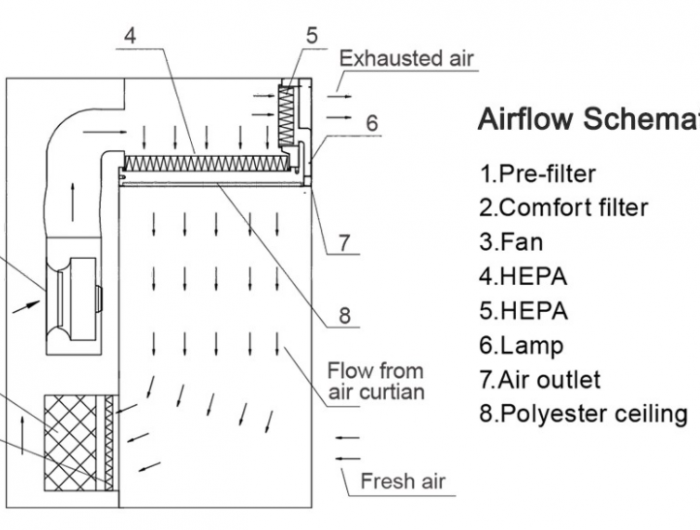

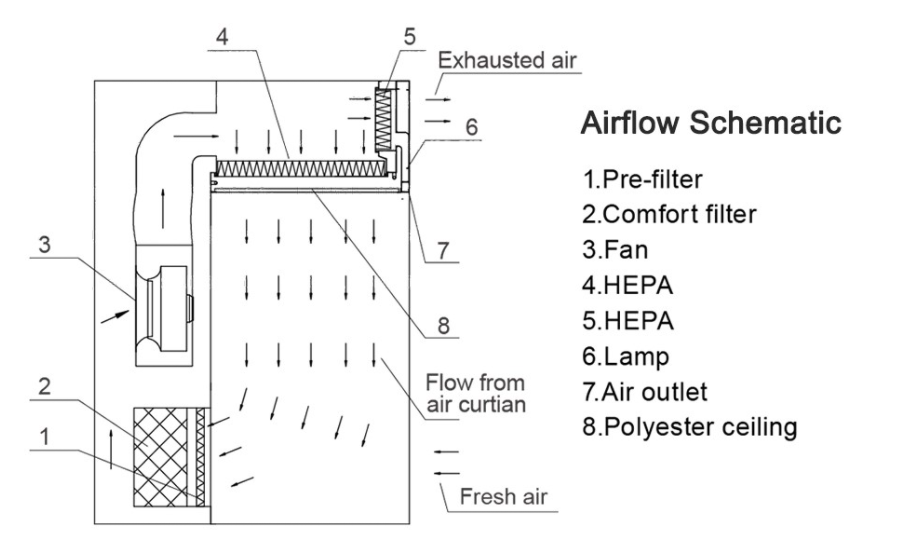

The air in the working compartment is sucked by the fan, passes through the coarse filter and the F8 bag filter and is pushed through the HEPA filter, from here creating a flow of stratimet gas from top to bottom. This gas flow along with the negative pressure generated in the working compartment will prevent toxic dirt from being released into the surrounding environment and protect the operator inside.

In addition, the air that passes through 3 layers of dust filter will always be ensured the necessary cleanliness (the clean level can reach Class 100).

Application of LAF Weighing

LAF scales are used a lot in the pharmaceutical industry; used to weigh and concoct harmful substances; avoid them escaping outside and protecting the manipulater during work.

It is also used in the electronics industry; biological research; vaccine manufacturing as well as other cleanliness requirements.