Biological implant cabinets

What is a biological implant cabinet?

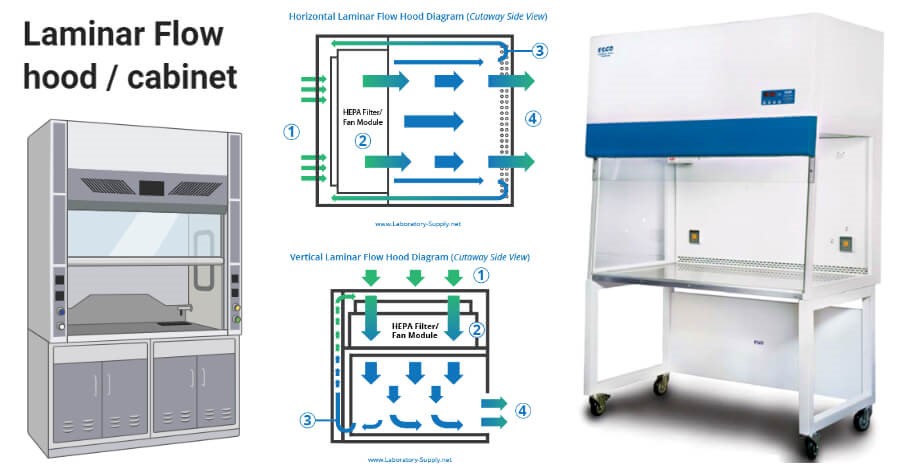

The Laminar Flow Hood (Safety bench) is a cleanroom device that creates a sterile, enclosed, clean environment in a certain space by creating a steady flow of casable air to protect the pattern from infection.

This device is often used in tissue-cell culture, culture of non-hazardous microorganisms or in the production of semiconductor electronic components that are susceptible to dust.

Bio-implant cabinet structure

A biological implant cabinet consists of 5 main parts:

– Cabinet body: usually made from stainless steel or powder coated steel. The shields around the cabinet body are usually made of stainless steel or glass, capable of insulation. The cabinet body is minimized the folds, reducing the dead angle for easy cleaning.

The working area is a flat surface, usually made from stainless steel.

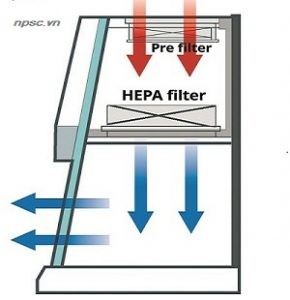

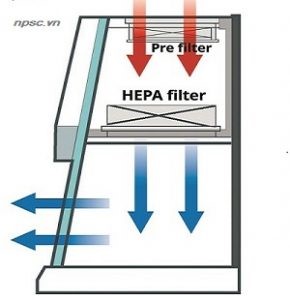

– Air filtration: consists of 2 types of filter: coarse filtration and HEPA filter.

– Fan: draws air from the surrounding environment, through filtration and forms a casable flow in the working compartment.

– Lamps: there are 2 types of lights: UV lamps used for sterilization and lamps.

Microbiological implant cabinet structure

Classification of biological implant cabinets

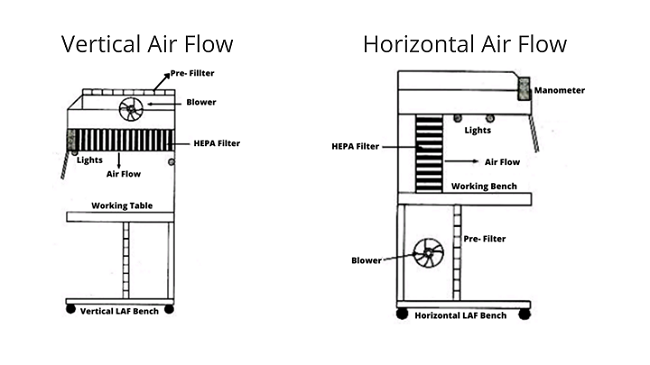

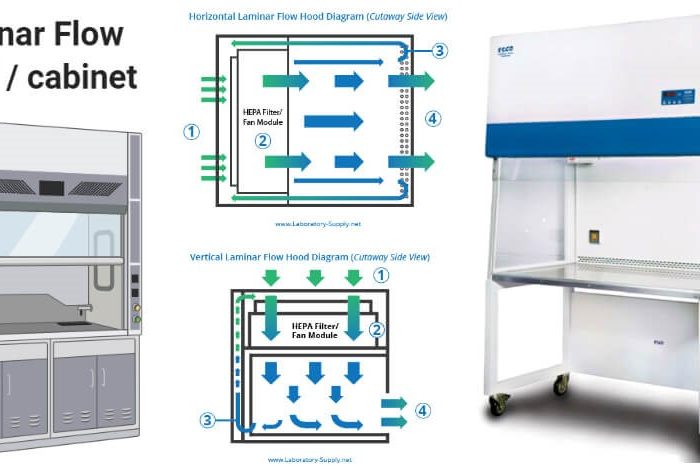

The implant is divided into two types:

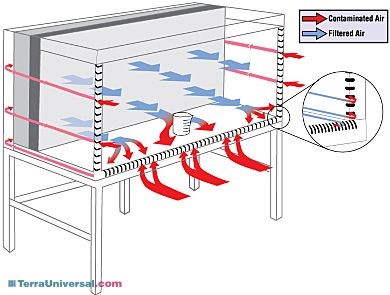

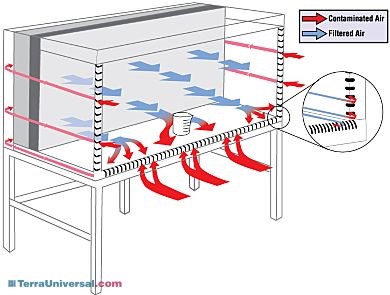

– Horizontal Flow Bio-Implant Cabinet: The clean air in the cabinet is blown from back to front.

The advantage of this type of cabinet is that the air flow moves horizontally, so it is less likely to pollute the sample, in addition it is also less disruptive to the surface. This type of cabinet is especially suitable for clean rooms with low ceiling height.

Horizontal Laminar Airflow Cabinet

However, due to the flow of air directly into the person, the safety of this type of cabinet is not high.

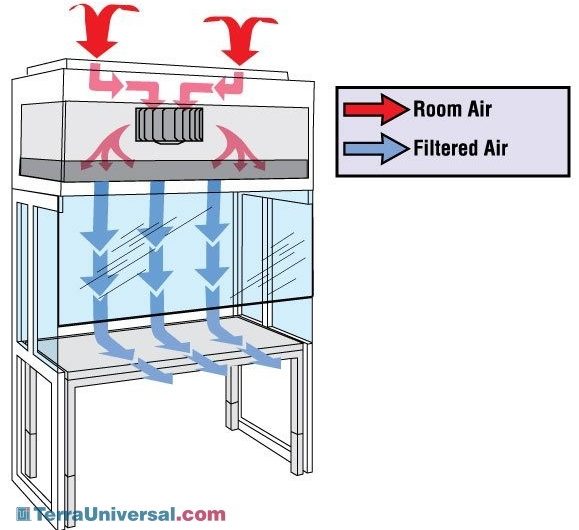

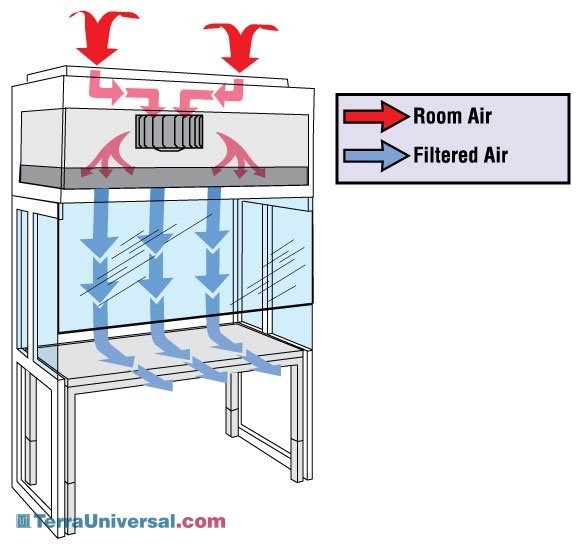

– Vertical Flow Bio-Implant Cabinet: The clean air flow is blown vertically from top to bottom, the gas escapes through the work door and the back door below.

Thanks to the upper glass, this cabinet design helps the operator not to be in direct contact with the flow of gas that smells unpleasant or exhaustive during the reaction. Vertical air flow reduces the rate of cross-contamination of the samples, in addition, this type of cabinet is also safer than horizontal flow cabinets.

Horizontal Laminar Airflow Cabinet

Operating principles

First, air passes through the coarse filter to filter large particles of dust, then passes through the fan and is blown towards the HEPA filter. The air when passing through the HEPA filter is retained most of the dirt, bacteria, fungi into clean air into the working room. After that, a large part of the gas will escape through the work door, the rest through the eduary under the wall back to the circulation in the system. The flow of casable air in the working compartment is always maintained at a stable speed and higher pressure than the surrounding environment to prevent the penetration of polluted outside air into the cabinet.

Working Principles of Microbiological Implants

Some notes during operation.

– Before operating the cabinet, make sure that nothing is easily affected by the UV rays in the cabinet.

– Close the protective glass door, then turn on the UV light for about 15 minutes to disinfect the work surface.

– After the UV light is turned off for 10 minutes, turn on the fan for about 5 minutes, then use the implant cabinet.

– Don’t work when the UV light is on.

– Do not use fans and UV lights at the same time.

Application

Bio-implantation cabinets are often used in laboratories, for pollution-sensitive processes (such as tissue culture or manipulation of dust-sensitive electronic devices), especially in the pharmaceutical industry, the preparation of drugs is often carried out in the implant cabinet to ensure the environment is particle-free during manipulation.