What is the GMP-WHO standard?

Pharmaceuticals (also known as medicines) are indispensable products in the prevention, healing, and adjustment of physiological functions of the body.

Due to the direct impact on health, human life, pharmaceuticals in any country are strictly controlled by state management agencies. Accordingly, all laws, circulars and guidelines are geared towards the two most important characteristics of pharmaceuticals: Safety and Quality. To ensure those two characteristics, products must be controlled from the beginning until commercially available. In which the stage of product creation in manufacturing plants plays the most important role.

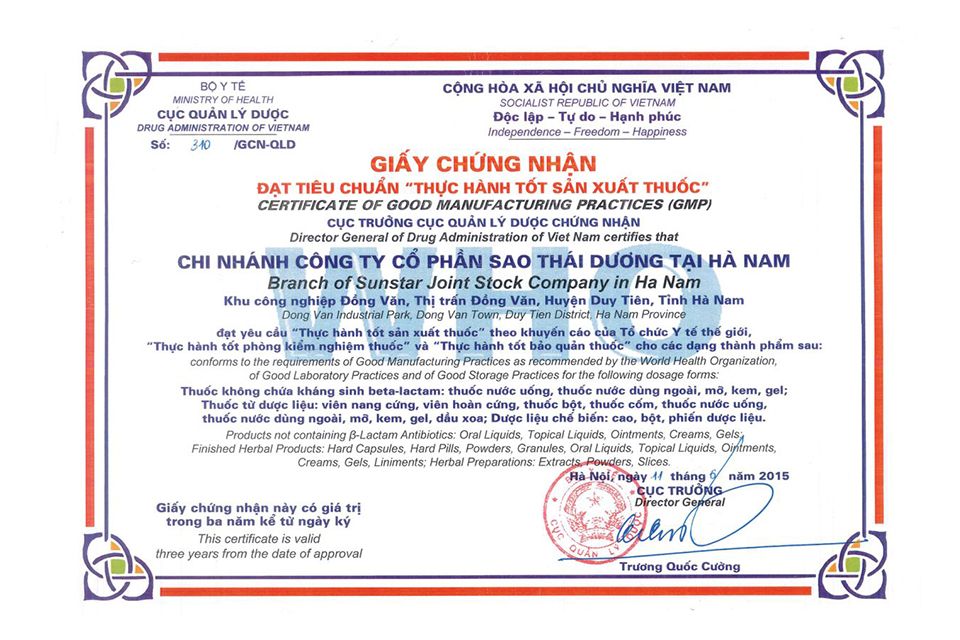

The World Health Organization (WHO) has drafted and issued good practice guidelines (GMP) or GMP-WHO standards as a fundamental basis for Member States to apply to control the production of pharmaceutical companies in the country. Many countries, including Vietnam, have used this standard as legal documents to show the mandatory nature of the application of GMP-WHO standards in pharmaceutical production.

For that purpose, GMP-WHO is defined as follows: “GMP-WHO is a guidance system to ensure pharmaceutical products are produced in a uniform manner and in accordance with established quality requirements.”