Production process of medicinal products

According to the World Health Organization in a 2016 study, about 84% of the world’s population uses medicinal drugs. Especially in Eastern countries including Vietnam, pharmaceuticals and medicinal products have become an important part of the field of medicine and pharmacy.

Medicinal herbs are derived from many different ingredients in nature such as from eastern objects, microorganisms or most commonly, herbs that are good for human health. Over the course of thousands of years, people discovered many new medicinal herbs that have more uses as well as a variety of preparations. So what is the process of producing medicinal products? Let’s explore with us in the following article.

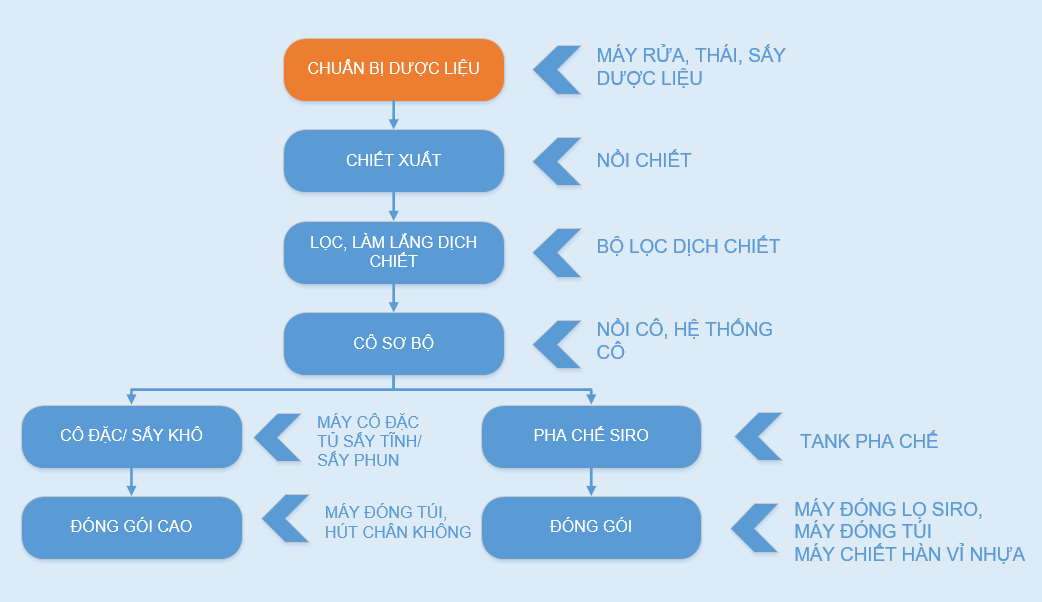

The process of producing medicinal products: high, syrup..

Production process of medicinal products

Material preparation stage::

Preparation of medicinal herbs should meet standards, carry out the steps of washing, drying, drying, finely chopping.

Extraction phase:

The process of using solvents separates dissolved substances from medicinal herbs. The most commonly used solvents are water and alcohol. The product obtained by the extraction process is called the extract.

For medicinal extract, many devices can be used to perform such as open extract pots, pressure reduceers, circulating pressure reduction extraction systems … With each type of production equipment has its own advantages and disadvantages.

-

Open Extract Pot

As a traditional extraction device, there are advantages that the investment cost is low, easy to operate but this method has many disadvantages such as high extraction temperature is not suitable for pharmaceutical substances that are easily decomposed by heat, do not recover solvents, low extraction efficiency.

-

Pressure ReduceEr Pot:

Using vacuum pressure to extract, the biggest advantage when extracting pressure will help reduce the boiling temperature of the solvent, improve the quality and keep the pharmaceutical substances.

-

Circulatory pressure reduction system:

It is a gradual extraction method that is commonly applied in modern production with many advantages such as solvent saving, high performance, superior product quality, closed process from extraction, filtration, concentrate …

Filtering and sedimentation phase:

The extract after the extract is also mixed with unwanted impurities. The extract is extracted through a filtering device to remove these components.

Condensing phase::

The extract after filtration, deposition is very thin, needs to be more concentrate. In production there are many techniques and methods of concentrate.

The stage she preliminarily can use her method with the open pot, she reduces pressure, she circulates compulsively. Then depending on the purpose of use can be further dried by spray drying, drying with static drying cabinet …

Vacuum circulation extraction system::

It is a package solution that integrates the stages of extraction, filtration, concentrate in the same machine.

Concentrate extraction is made under conditions of reduced pressure to help the active ingredients present in the pharmaceutical not to be damaged and remove impurity components that are not valuable.

With the solvent being circulated, it will only need to grant 1 amount of the original solvent 2-3 times the medicinal. Compared to other methods of extraction, this solution secretes solvents up to 200-300%.

The integration of production stages into a system helps the production process to be closed, reduce environmental pollution and cross-contamination of products, reduce installation area and save production costs.

T&T Company’s Vacuum Circulatory Concentrate Extraction System

Syrup concoction:

Using extracts, concoct additional ingredients needed to obtain the product is syrup.

Syrup packing phase:

Depending on the customer’s requirements, there are different packaging methods. This stage needs to be carried out to ensure accurate extraction, packaging is highly aesthetic.

+ Pack 5ml, 10ml syrup: Use fluid packing machines.

+ Bottled syrup: Use a bottled machine, solution jar.

+ Closing syrup in the form of plastic blister pipe: Use a 5-needle, 15-needle plastic blister welding machine.

High drying phase:

For high-drying can use static dryers, spray dryers for drying. Spray dryer is suitable for drying for high productivity, fast drying time.

For advice, support more information about the process of manufacturing pharmaceutical products – HEALTH FOOD, please contact:

GMP Groups Joint Stock Company

Head office: Lot LK20.8, Ecoriver Eco-Investor, Hai Tan Ward, Hai Duong City, Hai Duong Province

Hotline: 0945.255.457

Website: gmpgroups.com.vn

Email: info@gmpgroups.com.vn