Health-protective food cleanroom? Health Protection Food Cleanroom Standards

Building a health-protecting food clean room (BVSK) is a need of any business that wants to pursue this field. However, the design and construction of food cleanrooms requires many strict standards and requirements.

So what is a BVSK food cleanroom? What standards does the design and construction of food cleanrooms require?

GMP Groups will answer the above questions through the following article.

What is a health-protective food cleanroom?

First, we need to understand the clean room. Clean rooms are specially designed workspaces. There parameters such as urinary concentration, temperature, humidity, pressure, microbial limits,… Controlled and restricted.

Clean rooms are often applied to areas that require strict safety and quality requirements. Such areas include surgical and pasteurization areas; manufacturing cosmetics, pharmaceuticals, electronic components.

Health protection is a cleanroom system applied in the field of food production. Thanks to cleanrooms, functional foods, health-protective foods are produced in sterile environments; according to the best production and preservation standards. From there, the undesirable effects in the process of using the product are minimized.

Why do health food factories need clean rooms?

Health-protecting foods are products that directly impact human health. They need to be strictly controlled for safety and quality requirements right from the stage of production.

In the production process, the environment is the factor that most affects the quality of the product. Depending on the production stages, the level of environmental control will vary. In particular, the environmental stages of open contact with the product must be strictly controlled. To control the environment at these stages, the environment must be in a “clean room” space.

In the Health Protection Food CleanRoom, the clean area is maintained at appropriate clean standards; air filtered through the filter membrane has appropriate filtration performance; at the same time, people and/or machinery and materials entering and exiting the area are passed through airlocks. The above factors have ensured that the production of health-protective foods reaches sterile levels.

As such, cleanrooms are a mandatory and indispensable factor in health food factories. When appraising, cleanrooms also play a decisive role in the factory meeting GMP standards.

Cleanroom for Food Production Health Protection

Requirements and standards of health protection food cleanroom

Clean levels

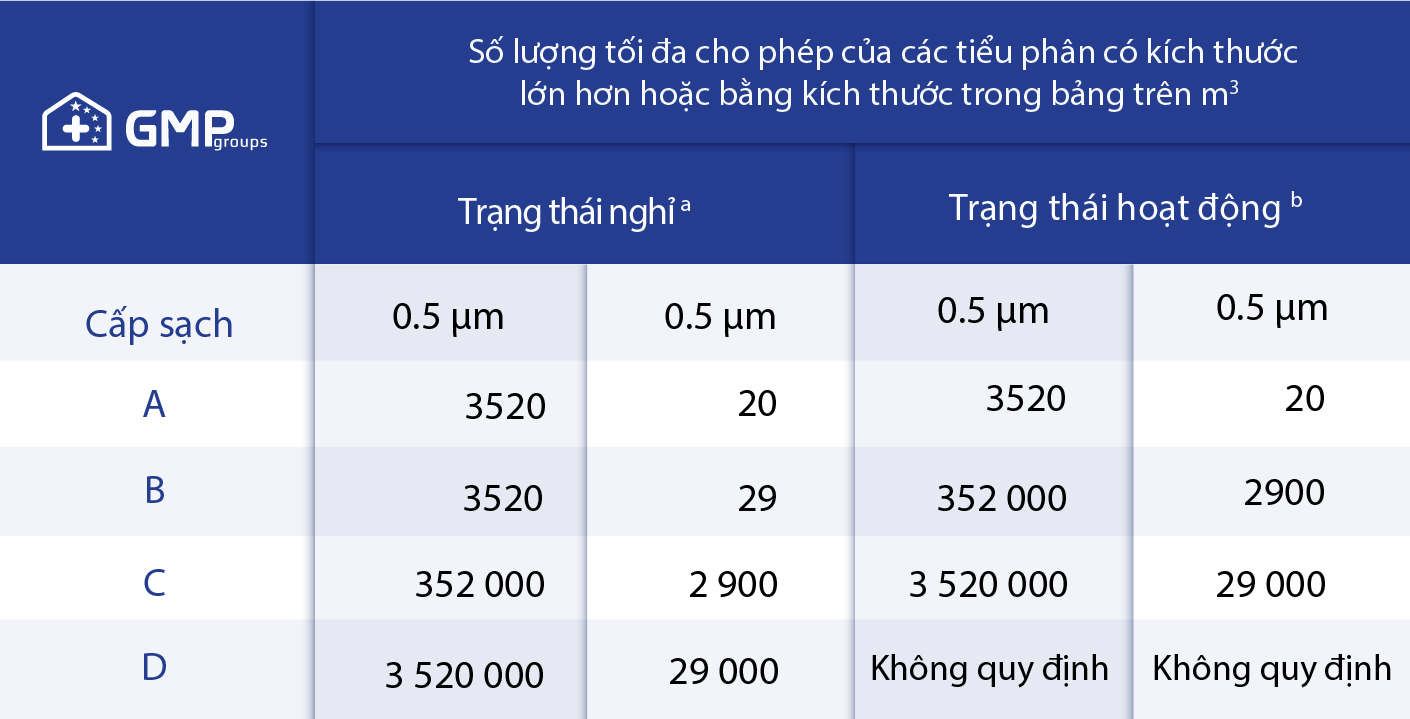

Depending on the product produced, the cleanroom is divided into various levels of cleanliness. This is aimed at controlling environmental factors, especially urinary concentration and microbial limits. In areas with cleanroom applications, cleanroom levels are classified on the ISO 14644 platform.

For Health Protection Foods, the products are mainly used for human use through eating. Therefore, the minimum and often applied clean grade is level D. Depending on the desire to control the quality of the product, manufacturers can apply higher levels of cleanliness.

Clean levels in food cleanrooms Protect health

Principles of design and construction of clean rooms

In order to control environmental factors well, health protection food cleanrooms must adhere to the following principles:

Design and layout

Clean rooms must be designed and arranged so that production is carried out in successive areas in a reasonable order corresponding to the order of production activities.

Working area

During the production process, there must be enough area to arrange machinery and materials in order and reasonable. It is necessary to minimize the risk of confusion between products or components of the product. Avoid cross-contamination, minimize the risk of omissions or misalisnment of any production steps, inspections.

Contact surface

The surface of the clean room where direct contact with the open product must be smooth; There are no cracks, no openings. The surface must not be the source of accumulation and feces. They must allow for easy and effective cleaning of disinfection.

Difficult area to clean

Ducts, light troughs, ventilation points and other services must be designed and installed so as to avoid creating difficult niches for cleaning. At the same time, it is required to carry out maintenance and access to these services from outside the production area.

Drainage

The drainage lines must be large enough, designed and equipped to avoid reflux. If possible, avoid open drainage. In case the open exit is necessary, it is recommended to build a farm for easy cleaning and disinfection.

Ventilation

Cleanrooms must be well ventilated, have air control equipment (including air filtration equipment at sufficient levels to prevent contamination and cross-contamination as well as temperature control, and humidity if necessary) in accordance with the products being processed, in accordance with the operation performed and with the external environment.

GMP Groups – The design and construction of a clean food cleanroom to protect health all over the package

To ensure quality, clean rooms must be focused from the selection of locations and construction locations. Next is the design and construction phase. Finally, monitoring and due diligence. The market currently has many units constructing pharmaceutical cleanrooms, but most units are only capable of providing one of the stages of cleanroom construction, which makes businesses take longer and more time and costs.

GMP Groups Services

GMP is proud to be the construction unit, designing a comprehensive health protection food cleanroom, capable of bringing the most comprehensive and synchronous service. Comprise:

– Consulting services, designing healthy food cleanrooms

– Health Protection Food CleanRoom Construction Service

– Health Care CleanRoom Assessment and Evaluation Service

GMP Groups is a reputable health protection food cleanroom design and construction unitv

The reason to choose GMP Groups as the construction unit, designing health protection food cleanroom

In addition to the comprehensive service package, GMP groups is also selected by investors as a health protection food prevention service provider by:

– 3D design system and VR-360 virtual reality technology is a technological breakthrough of GMP Groups. This technology allows customers to experience the most vivid factory space and clean room right from the design stage.

– Experienced, enthusiastic, dedicated staff. GMP Groups’ employees are pharmacists and engineers who have been operating for 5-15 years in pharmaceutical companies.

– GMP Groups understands the production technology of each dosage form. From there, we will provide our customers with the most effective and suitable design solution.

– We understand the requirements of cleanroom, clean supply, machinery and human-human equipment in each stage of production. We can calculate for customers the requirements of area, air treatment system suitable, economical, most efficient.

Conclude

With the desire to provide a comprehensive service ecosystem related to the Health Food CleanRoom, GMP Groups will be the perfect choice for any customer’s needs.

For more information on CONSULTING – DESIGN – CONSTRUCTION OF CLEANROOMS, please contact:

GMP Groups

Head office: No 273 Hoa Ban, Ecoriver Eco-Investor, Hai Tan Ward, Hai Duong City, Hai Duong Province

Hotline: 0945.255.457 – Email: info@gmpgroups.com.vn – Web: gmpgroups.com.vn