The introduction of the GMP-HS standard

Health-protective foods (TPBVSK) are products used for the purpose of supporting treatment, improving recovery, promoting human health. TPBVSK is a product under the management of the Ministry of Health in the functional food group (as defined in the Food Safety Law 2010).

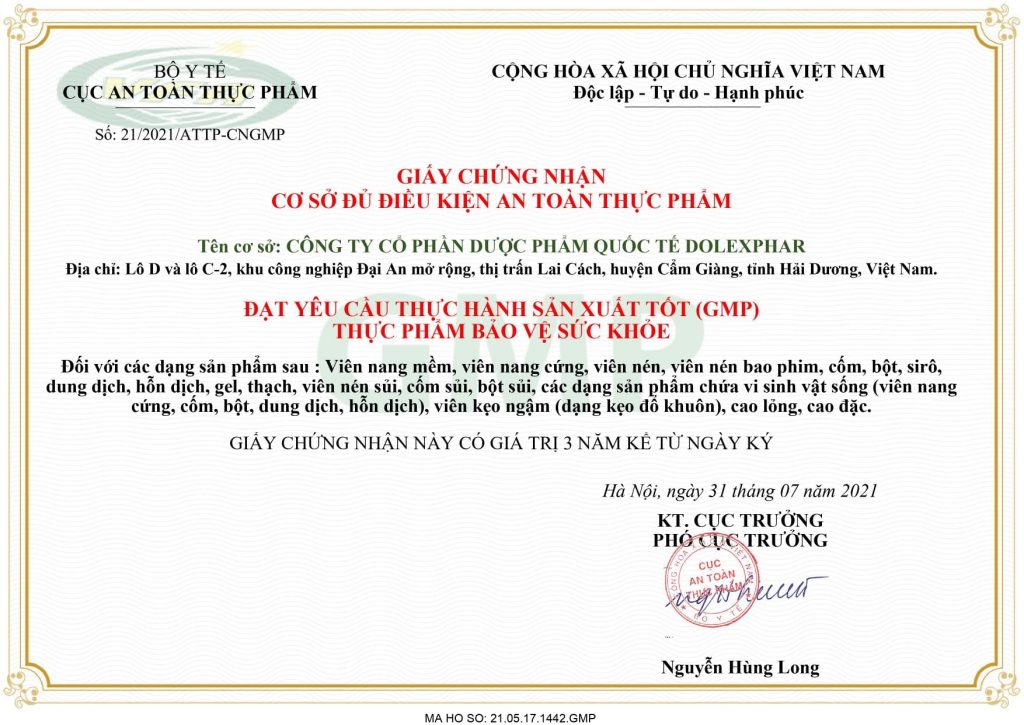

Enterprises wishing to produce TPBVSK must be granted a certificate of food safety eligibility by the Ministry of Health. Previously, the conditions of facilities for the production of TPBVSK were relatively general, as shown in Chapter IV of the Food Safety Law like many other foods. These conditions are then specified in more specific and detailed in Decree No. 67/2016/ND-CP exclusively for food groups under the management of the Ministry of Health.

Recognizing the risks to the safety and quality of TPBVSK, the regulations on the conditions of facilities for the production of TPBVSK are not really strict. Meanwhile, the dosage forms of TPBVSK are completely similar to pharmaceutical products. Based on the good practice guidelines (GMP) for pharmaceuticals, the Ministry of Health has drafted and issued the “Good Manufacturing Practice Guidelines (GMP) in the production and trading of health-protective foods” (Circular 18/2019/TT-BYT) referred to as “GMP-HS standard”.

Certificate of establishment meeting good manufacturing practice (GMP) Health Food