Building a clean, static room

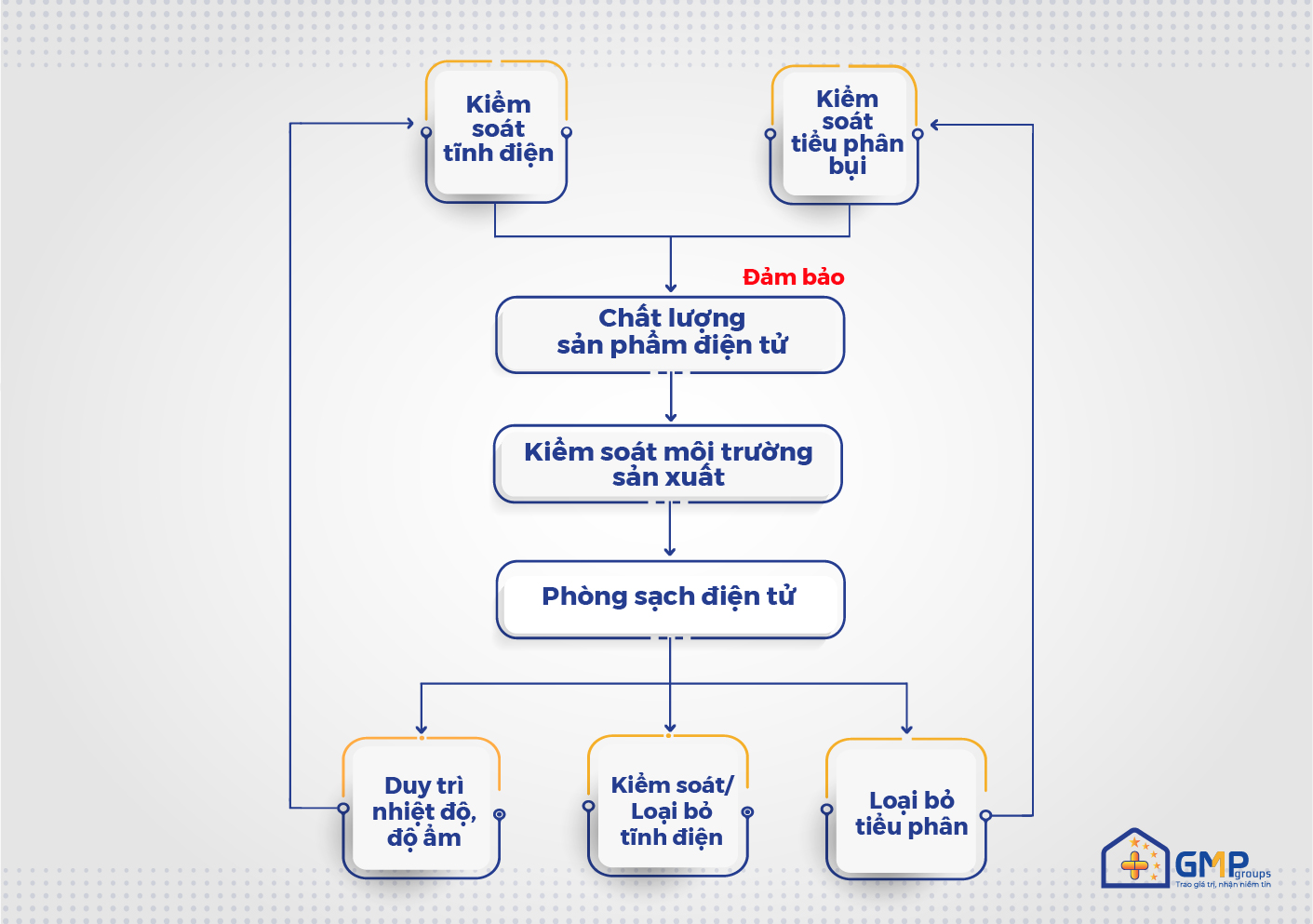

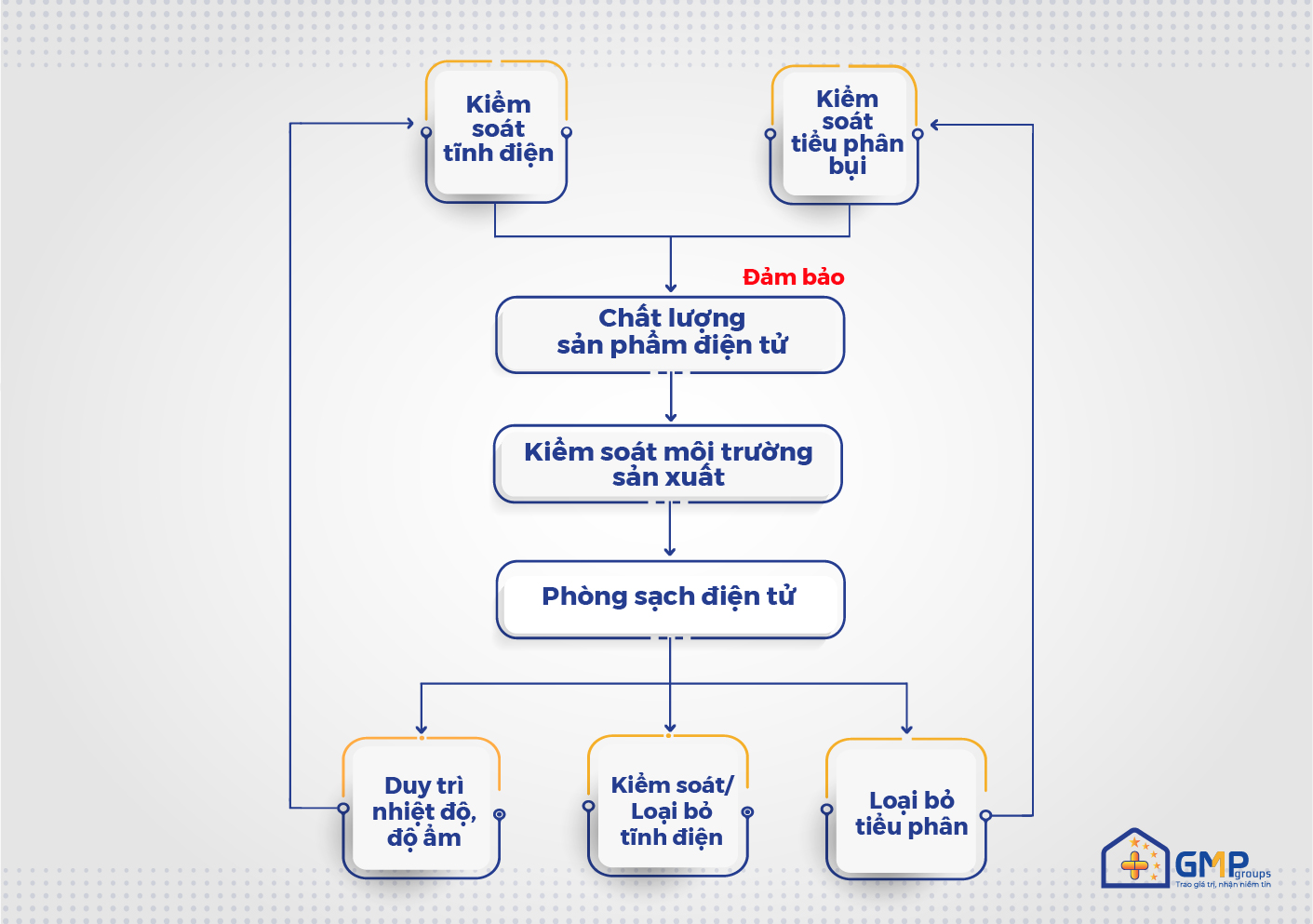

Electronics is an industry with very strict requirements for accuracy in each stage of production. Electronic components and microchips are considered the heart of each electronic product, only a small bolt can destroy electronic boards and chips. The production and assembly of electronic components from the beginning has needed to have a suitable environment to ensure humidity, ensuring the number of particult matter. Therefore, clean rooms are indispensable for electronic factories.

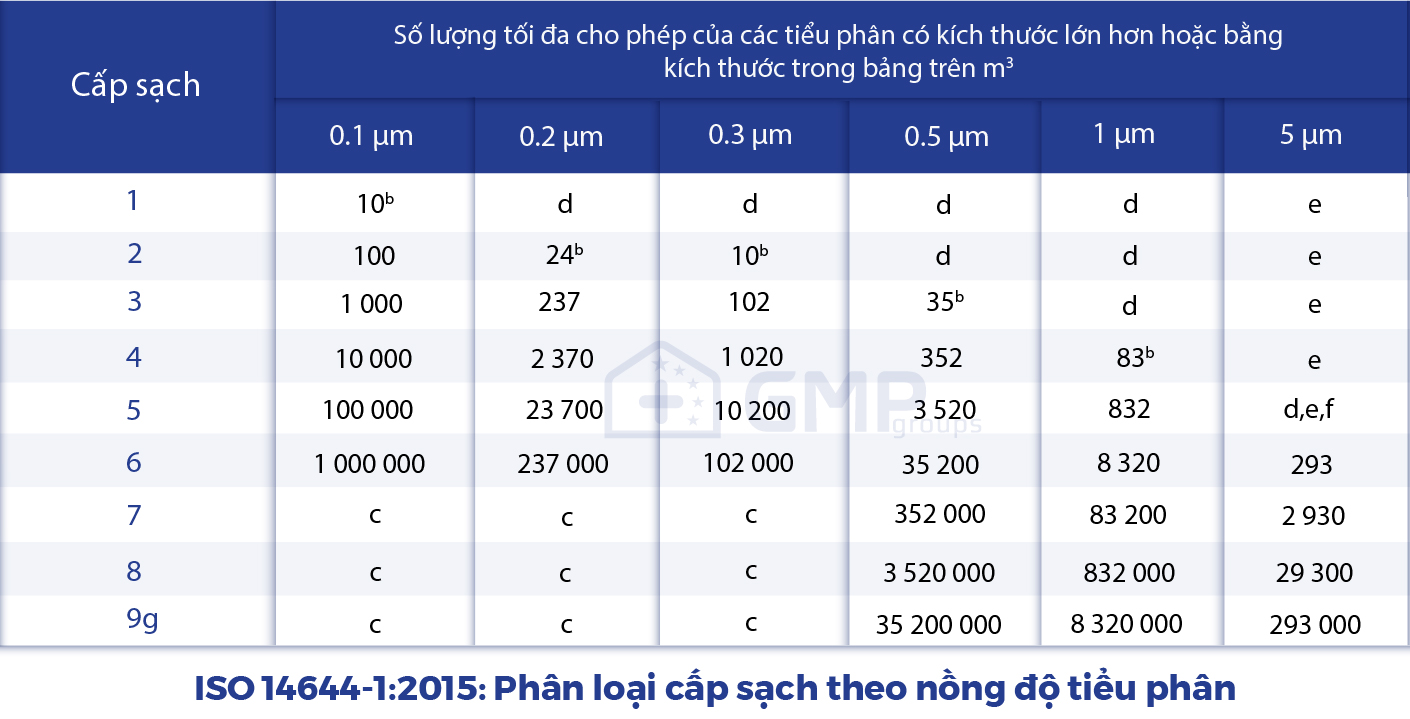

In the Vietnamese market, electronic cleanrooms usually apply one of the following two criteria:

Iso 14644-1 International Standard

Clean level gradually decreased from ISO 1 to ISO 8

Fed Std 209 E Standard

With reduced clean levels: from Class 1, Class 10, Class 100, Class 1000, Class 10,000, Class 100,000.

Other standards

Besides the two main standards, a few other standard parameters that need to be paid attention when building an electronic cleanroom include:

Temperature standard: The average temperature is from 20-26oC, this is a safe temperature for equipment as well as electronic components, so that the batteries operate stably. This standard will keep the welds or links from melting.

Humidity standard: Humidity should remain at an average of 18-55% depending on the type of component and the extent of human appearance in a cleanroom.

Dust standard: Control according to ISO-14644 and FS 209 standards.

Pressure standard: 15 – 45 Pa

Noise standard: 40 – 65 Db

Here’s an overview of GMP Groups’ e-commerce cleanroom service. For more information, please see more at: What is an electronic cleanroom? Standards of electronic cleanrooms

With the desire to bring a comprehensive service ecosystem related to the food sector, GMP Groups will be the perfect choice for any customer’s needs.

For more information on CONSULTING – DESIGN – CONSTRUCTION OF CLEANROOM, please contact:

GMP Groups Joint Stock Company

Head office: Lot LK20.8, Ecoriver Eco-Investor, Hai Tan Ward, Hai Duong City, Hai Duong Province

Hotline: 0945255457